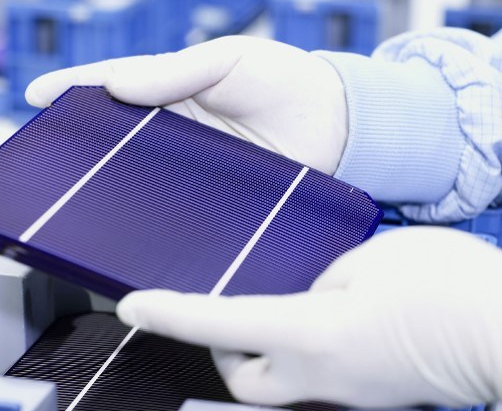

It may be possible to drive up solar PV plant output with better panel heat dissipation, but a better thermal model is necessary first.

A great way to reduce the cost of solar power is to increase the output of the solar plant. Solar photovoltaic (PV) panels lose efficiency when they operate at higher temperatures, and unfortunately, they generate heat and operate well above ambient temperature. So, a potential opportunity to boost power plant output is to dissipate heat better to drive up efficiency. After recently seeing a not-uncommon 7% thermal loss in a PVsyst simulation, my intention was to write about the value proposition for better panel heat transfer. However, it seems that panel thermal behavior in an operating plant is not very well understood. What seems to be needed first is further scientific study to understand what governs panel temperature in real solar plants. Then, a clear assessment could be made for the potential to boost output from better heat dissipation. Before the design engineers get to work, perhaps the boffins should have another go at it.

Continue reading “Solar Panel Operating Temperature? Call in the Boffins”